HVLS industrial fans stand out in the field of industrial ventilation due to their high efficiency and energy-saving characteristics. These fans achieve high airflow coverage through low-speed and large-diameter operation, effectively improving air circulation efficiency. Compared to traditional small fans or air conditioning systems, HVLS fans can create a comfortable microclimate in a wider space while significantly reducing energy consumption. Its energy-saving effect benefits from its design, which is usually equipped with efficient motors such as permanent magnet synchronous motors, as well as optimized fan blade designs, which help reduce energy consumption. In addition, the intelligent control system of HVLS fans can adjust the wind speed according to actual needs, further saving energy. In the pursuit of green manufacturing and sustainable development today, these characteristics of HVLS fans make them an ideal ventilation and cooling choice in industrial and commercial environments.

Professional optimized design of fan blades

.jpg)

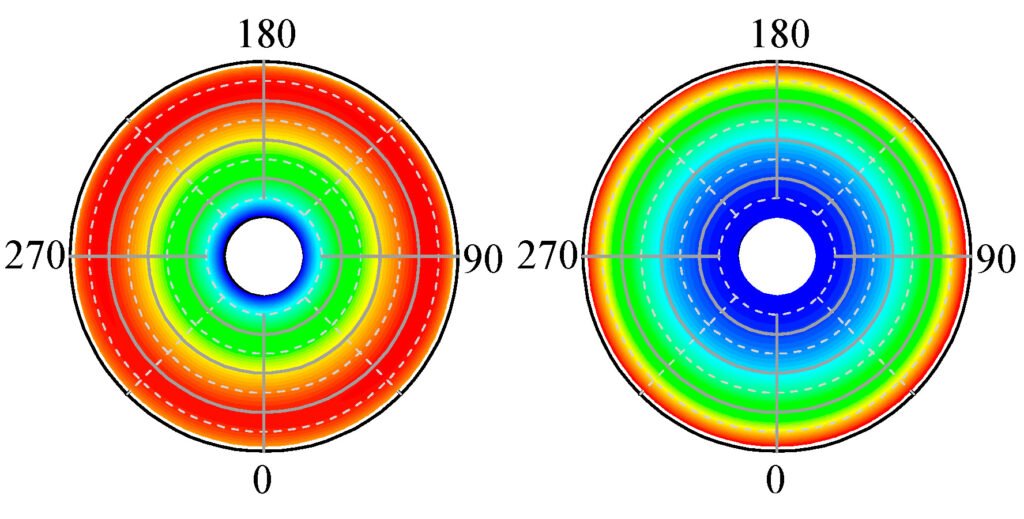

– Aerodynamic design

– Aluminum alloy profiles

– High strength

– Lightweight

– Long term stable use