Dealing with different scenarios calmly

1. Industrial environment: In large industrial facilities such as warehouses, workshops, factories, hangars, and distribution centers, HVLS fans can effectively reduce temperature, prevent heat stress, and improve work efficiency.

2. Agricultural facilities: HVLS fans were originally developed for livestock applications to cool cows and other animals, reducing heat stress.

3. Commercial space: In commercial spaces such as shopping malls, supermarkets, and sports venues, HVLS fans can increase air flow and improve customer comfort.

4. In public places such as exhibition centers, conference centers, schools, hospitals, etc.: HVLS fans can provide large-scale ventilation and cooling, improve air quality, and create a more comfortable environment for people.

5. Logistics and transportation industry: In logistics centers and distribution warehouses, HVLS fans help maintain a suitable storage environment for goods while providing comfortable working conditions for staff.

6. Special environment: In environments that require special ventilation conditions, such as chemical plants, mines, etc., HVLS fans can provide necessary air circulation to help eliminate harmful gases and protect the health of workers.

The use of permanent magnet synchronous motors (PMSM) in HVLS industrial fans has significant advantages in energy savings. PMSM motors, due to their high efficiency and high-power density characteristics, can provide powerful output power at lower energy consumption. This type of motor utilizes permanent magnet materials to generate a magnetic field, reducing the current required by traditional motors and thus reducing energy loss. In HVLS fans, this means that even at low speeds, the fan can generate a large amount of airflow while maintaining lower energy consumption.

In addition, the high efficiency of PMSM motors also means that their operating costs are relatively low throughout the entire usage cycle, which helps businesses reduce long-term energy expenses. The high-power density of the motor makes the fan design more compact, further reducing material usage and overall cost. At the same time, the long lifespan and low maintenance requirements of PMSM motors also save maintenance costs for enterprises, enhancing the comprehensive advantages of HVLS fans in energy conservation.

The design of PMSM motors reduces rotor losses and electromagnetic noise because they do not require additional electrical excitation, which reduces energy loss and noise generated during operation. In addition, the low-speed operating characteristics of HVLS fans mean that while generating a large amount of airflow, they do not produce high-frequency noise commonly seen in traditional high-speed fans.

Optimized blade design for smoother operation, further reducing noise generation.

This low-noise operation is crucial for creating a comfortable working environment, especially in industrial and commercial spaces that require low background noise. When employees work in such an environment, they not only enjoy the cooling and ventilation effects brought by HVLS fans, but also avoid noise interference, thereby improving work efficiency and overall job satisfaction.

Knowledge of HVLS Industrial Fans

- HVLS fans China manufacturers

- Factory large fans

- Workshop HVLS fans

- Key points of HVLS fans blade design

- Customized size and function of PMSM HVLS fan

- PMSM HVLS Fans Manufacturing Technology and Process Flow

- Technical advantages and innovation of PMSM HVLS ceiling fans

- HVLS Industrial Fans Intelligent Technology

- Advantages of using HVLS industrial large fans

- What are the types of HVLS industrial fans

- HVLS industrial fans in farms

- The cooling effect of HVLS industrial fans

- What types of motors are used for HVLS fans

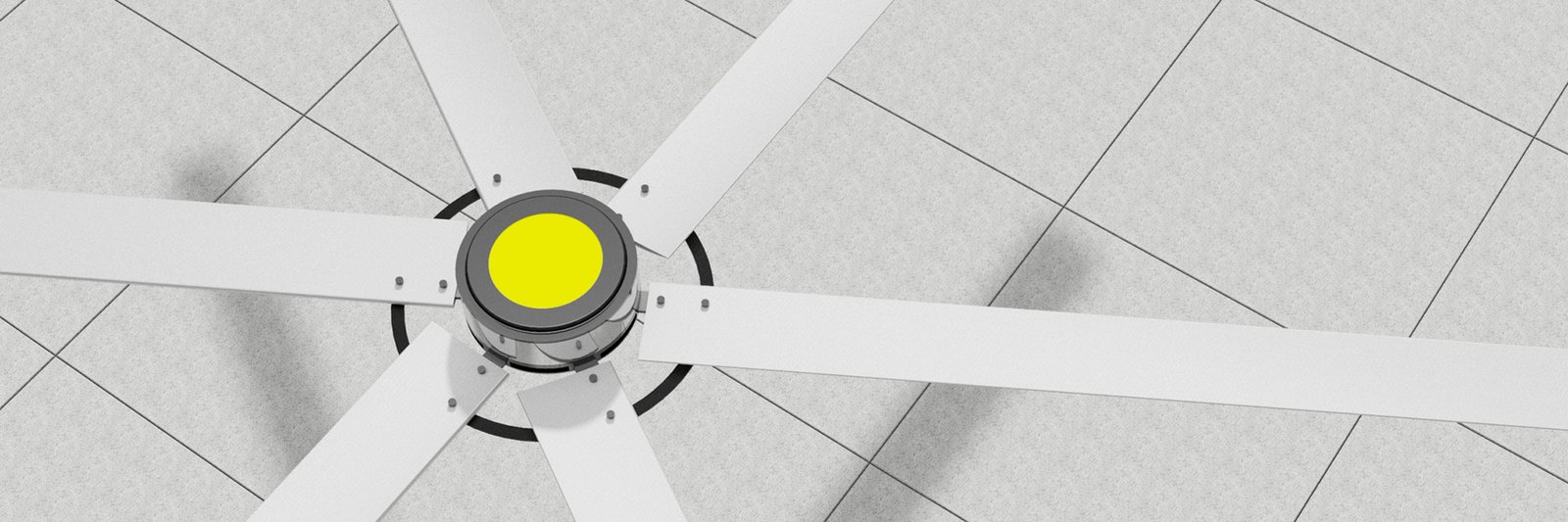

- The main structure of HVLS industrial fans

- How to choose the appropriate HVLS fan

- HVLS fans for industrial buildings