Using Permanent Magnet Synchronous Motor (PMSM)

The high-power density of PMSM motors allows for powerful performance in compact spaces. Accurate control capabilities, such as stepless speed regulation and precise positioning, enable PMSM motors to perform excellently in situations that require precise operation. Low noise and long lifespan further enhance their attractiveness, especially in noise sensitive environments. The environmentally friendly characteristics of PMSM motors reduce grid losses and carbon emissions.

The benefits of using PMSM (Permanent Magnet Synchronous Motor) for HVLS industrial fans mainly include the following points:

1. High efficiency: PMSM motors use permanent magnet excitation to reduce the demand for excitation current, thereby reducing energy loss and improving overall efficiency. This makes PMSM more energy-efficient than traditional induction motors during operation.

2. High power density: Due to the use of permanent magnet materials, PMSMs can provide larger output power in smaller volumes and weights, which makes them very advantageous in space limited applications.

3. High torque density: PMSM motors can generate higher torque at lower speeds, which is crucial for applications that require high starting torque and has many benefits for HVLS industrial fans.

4. High power factor: The power factor of PMSM motors is close to 1, which means that most of the input power of the motor is converted into useful mechanical power, reducing the loss of reactive power, making it more energy-efficient for HVLS fans.

5. Precision control: PMSM motors are usually equipped with advanced control systems, such as vector control or field oriented control (FOC), which can achieve precise speed and torque control, improving the response speed and accuracy of the system.

6. Low maintenance cost: Due to the absence of vulnerable components such as carbon brushes and commutators, PMSM motors have lower maintenance costs and longer service life, which can effectively extend the service life of HVLS fans.

7. Low noise operation: PMSM motors have lower operating noise due to their smaller air gap, less magnetic flux leakage, and smooth operation.

8. Good starting performance: PMSM motors can provide high starting torque during starting, which is crucial for applications that require fast starting.

9. Environmentally friendly: The high efficiency of PMSM motors helps to reduce energy consumption, thereby reducing its impact on the environment.

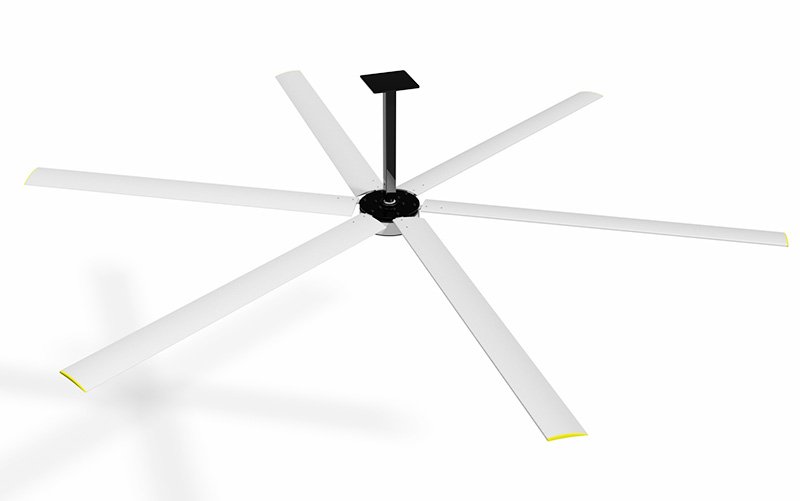

10. Strong adaptability: The HVLS industrial fan made of PMSM motor is suitable for various application scenarios, such as farms, shopping malls, factory workshops, etc.

The HVLS fans using PMSM are designed to operate at low speeds, which means they can move a large amount of air with less electricity consumption. Compared to traditional high-speed fans, HVLS fans consume less energy when providing the same air volume.