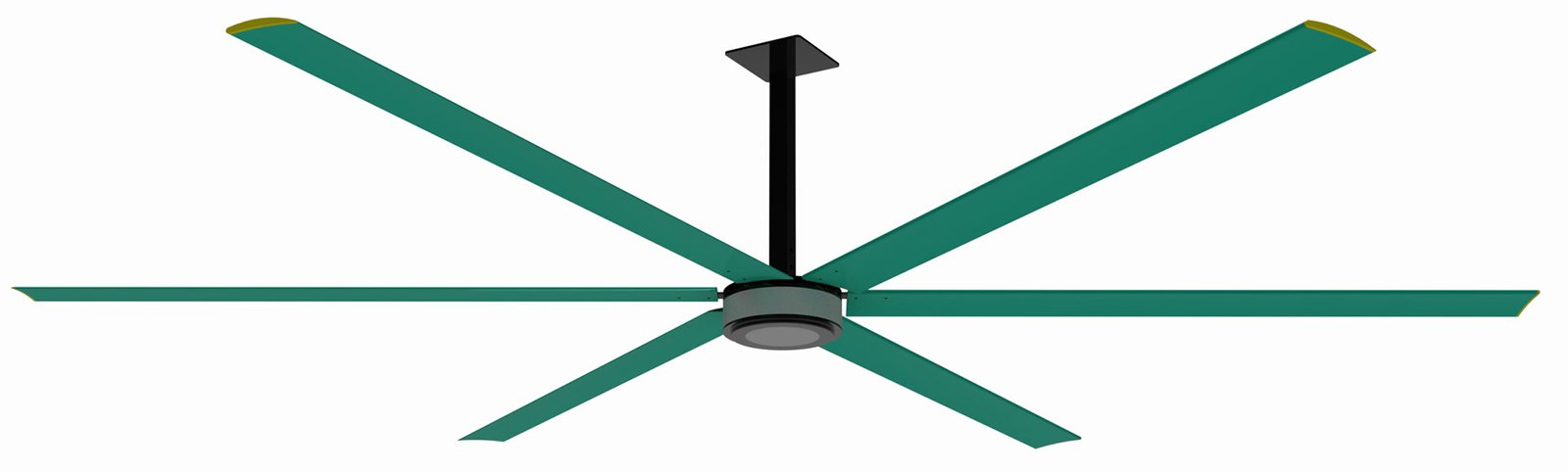

Installation method of HVLS industrial fan

The installation of HVLS fans is usually done through roof suspension, which is particularly suitable for large spaces such as warehouses, barns, hangars, and distribution centers. Proper installation not only reduces the failure rate of the fan, but most importantly, ensures the safety and stability of the user’s use. When installing, it is also necessary to consider the diameter of the fan blades to ensure sufficient airflow coverage in the area. For example, a fan with a diameter of 7.3 meters can have a coverage radius of 22 meters and a coverage area of 1500 square meters. The installation conditions include factors such as installation height and obstacles on the ground, which can affect the airflow effect of the fan.

Regarding the installation of HVLS industrial ceiling fans

The installation method of HVLS (High Volume, Low Speed) industrial fans usually involves the following key steps:

1. Choose a suitable location: Firstly, it is necessary to determine the installation position of the fan. This usually depends on the size of the area to be covered, the height of the space, and the size of the fan. The ideal location is for the fan to evenly cover the entire space while avoiding direct alignment with personnel work areas.

2. Installation bracket: Install the bracket above the designated position. The bracket needs to be sturdy enough to support the weight of the fan and withstand the pressure generated during operation. Brackets are usually made of steel and need to be firmly connected to building structures such as beams or trusses.

3. Lifting the fan: Lift the fan onto the bracket. This may require the use of a crane or elevator to ensure that the fan can be safely raised to the appropriate height. During the lifting process, it is necessary to ensure the horizontal and vertical alignment of the fan.

4. Connect the power supply and control system: After installing the fan, it is necessary to connect the power cord and control system. This may include speed controllers, timers, or other intelligent control devices. Ensure that all electrical connections comply with local electrical safety regulations.

5. Safety inspection: Conduct a safety inspection before the fan is running, including checking whether all bolts are tightened, whether the fan blades are balanced, and whether there are any potential safety hazards.

6. Debugging and Testing: Finally, debug and test the fan to ensure it can run smoothly at different speed settings, and check if the airflow coverage meets expectations.