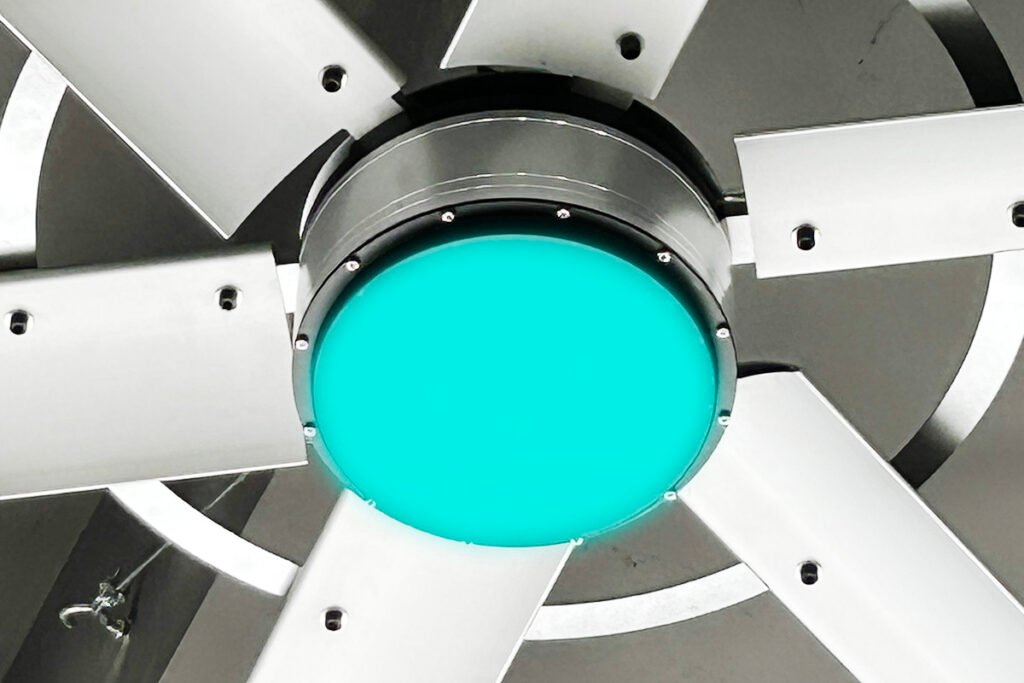

PMSM HVLS (Permanent Magnet Synchronous Motor High Volume, Low-Speed) fans are large industrial fans known for their high efficiency, high air volume, low energy consumption, and low noise. Here are the technical features of PMSM HVLS fans, combining aspects of PMSM motors, fan blades, noise control, and fluid dynamics analysis:

PMSM Motor Technical Features

- High Efficiency and Power Density: PMSM motors are widely used in HVLS fans due to their high efficiency and power density. These motors can provide significant output power at lower energy consumption, thereby enhancing the overall efficiency of the fan.

- Vector Control Technology: Through vector control technology, PMSM motors can achieve decoupling control of torque and flux, allowing the motor to maintain high efficiency under varying operating conditions and further improving the fan’s airflow efficiency.

- High Power Factor: PMSM motors typically have a high power factor, reducing the generation of reactive power and increasing energy utilization.

Fan Blade Design Features

- Large Diameter and Low-Speed Operation: HVLS fan blades usually have a large diameter, combined with a low-speed operation design, which can generate a large volume of airflow at a lower RPM, effectively covering a larger area.

- Aerodynamic Optimization: The shape and angle of the blades are optimized for aerodynamics to reduce air resistance and improve the uniformity of airflow. Such design helps enhance airflow efficiency and ensures effective air circulation in the space.

Noise Control

- Electromagnetic Noise Optimization: By optimizing electromagnetic forces (reducing excitation forces) and reducing the impact of magnetostrictive forces on motor noise, the noise generated during fan operation is effectively reduced.

- Structural Design: The fan’s structural design considers noise reduction needs, such as using inclined stators or forming optimal slots on the rotor poles to reduce the amplitude of electromagnetic forces near the modal frequency.

Fluid Dynamics Analysis

- Airflow Simulation: Computational Fluid Dynamics (CFD) simulations can predict the airflow distribution, velocity fields, and pressure fields of the fan under different operating conditions, thereby optimizing the fan’s airflow performance.

- Fluid-Structure Interaction Analysis: Through fluid-structure interaction dynamics assessment, the vibration and deformation of fan blades under the influence of airflow are analyzed, optimizing the structural design to enhance the fan’s stability and durability.

In summary, PMSM HVLS fans achieve excellent performance in terms of high efficiency, high air volume, low energy consumption, and low noise by integrating advanced PMSM motor technology, well-designed fan blades, effective noise control measures, and in-depth fluid dynamics analysis. This makes them widely used in industries, commercial spaces, and public areas.